3D Printed Prosthetics: How Markforged’s 3D printing technology is helping people in need

With the advent of 3D printing, along with the most advanced manufacturing materials, innovators are providing a greater level of independence and better quality of life for the amputees and those affected by neurological disorders.

There are millions of people around the world who depend on prosthetics and other mobility devices to negotiate the world around them. Yet, access to prosthetics care and technology depends on the country’s available resources and technological advancements. In fact, according to the World Health Organization, “only 1 in 10 persons located in low-resource areas has access to adequate prosthetic technology.”

The advancement in 3D printing technology has enabled clinicians and engineers to push boundaries and change the face of medical industries to provide cutting edge devices. Additive manufacturing also helps develop durable, high-functioning prosthetics more affordably, allowing more people from resource-starved areas access to greater mobility.

Toughware Prosthetics

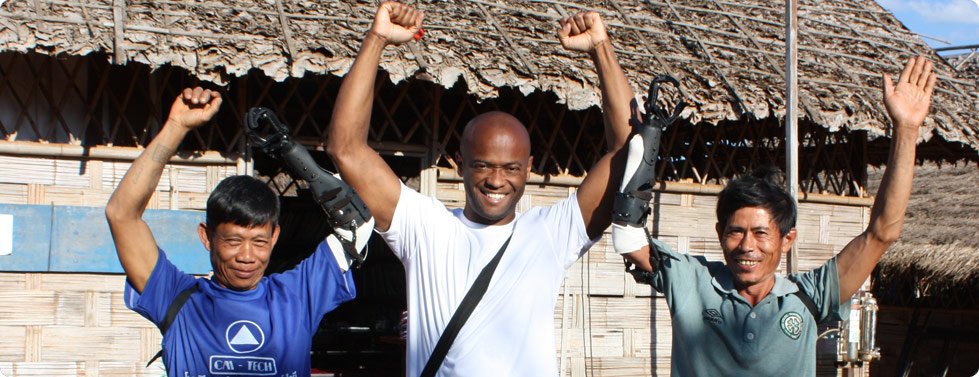

Bradley Veatch, President, and CEO of Colorado-based Toughware Prosthetics are committed to creating affordable and convenient prosthetics for the underserved amputee community;

The use of the latest technology has given the freedom to Veatch to design and manufacture high-functioning prosthetics. He was extremely successful in the engineering sense, he recalls, “but I had this device that was so expensive that there were probably ten people in the United States that could afford the thing.”

The experience taught Veatch that the world is not searching for more sophisticated and expensive prosthetics, but rather they want more enduring and convenient options. So he changed his career path and decided to focus on creating more affordable and accessible prostheses for people in developing countries. He developed a new design which was ideal for those who may rely heavily on physical activity for their daily needs, or who may not have a reliable power source or the ability to access to a computer – accessories mandatory for other, more complex designs. “I wanted to actually focus on creating technologies that were appropriate and that could do what these people needed them to do, like swing a hammer, carry a 22-pound bucket of water, or lift a child,” says Veatch.

The new design concept was more complex than the traditional ones. It became an issue for Veatch because the design needs to be sent out to be prototyped before actual production. He would also have to wait upwards of six weeks to get them back, slowing down his entire design process.

The Solution

Markforged’s 3D printing technology was the solution for Veatch and his team. They decided to purchase a Markforged composite 3D printer. This 3D printer from Markforged is capable of printing in continuous carbon fiber. “As we got further on some of our projects I became more interested because we needed high strength in some of the parts,” says Veatch. When some budget became available to the team, they jumped on the opportunity and bought a Markforged desktop printer.

The manufacturing of some elements became easier for Veatch and his team, as the Markforged 3D printer allows them to print their design which is not only stronger but also quicker; “I wasn’t interested in losing six weeks of schedule while things were made in a machine shop,” he says. “I’m actually able to get a lot more done in a much more concentrated timeframe. I can produce an engineering design … print and then begin running tests, sometimes even the same day. I can print what I need, when I need it, and continue with my iterative design process.”

The use of Markforged additive manufacturing machines helped Toughware to cut the cost and time in prototyping. One prototype bracket, for example, was going to cost Veatch $65 to be machined out of aluminium but was only a few dollars when printed using his Markforged composite printer, according to Veatch. “And I was able to put carbon fiber in it, which was really cool. So it was strong and just what I was looking for in the application time. And it only took five hours to print!” Veatch and his team are now able to quickly iterate on new designs and don’t have to worry about long lead times.