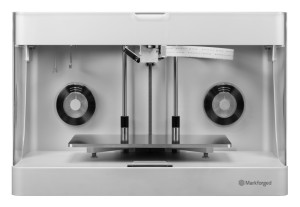

Functional 3D Protyping with Markforged Printers – Autometrix Customer Success Story

About Autometrix

Autometrix is a company that designs high tech cutting equipment for the textiles industry. Their main job scope delves into precision cutting in the textile industry. They also develop the software to drive the machines.

Problems faced

Autometrix were familiar with 3D Printing. The cause of concern however was whether these 3D Printed parts had the desired strength, stiffness and durability to be actually tested in a real wolrd environment. The team soon realized that the Markforged printers could produce actual functional 3D Prototypes and End use parts right off the print bed and this was something that could value add their business.

Functional 3D Prototyping with Markforged – Project Undertaken by Autometrix

The main project involved printing an entire cutting head and the team found that cutting head alone was much lighter than the original head being produced. Functional 3D Prototyping with the Markforged printer helped save time taken to prototype a particular design as compared to before. Weight saving is an important feature when utilizing a Markforged printer. With the product being lighter, it could help increase in the movement of a particular part giving it a higher acceleration and speed at any given point of time. This in turn contributed to less wear and tear to the machine.

Benefits Gained with the Use of Markforged Printers

The Markforged printer allows it users to reinforce their 3D designs with different composites to become actual functional 3D prototypes. Composites such as Carbon Fiber, Kevlar, Fiberglass and High Strength High Temperature Fiberglass are current composites that can be used. With the Eiger software created by the Markforged team, It also allows the user to manually decide where composite fibers can be added to further strengthen the product. One can choose and isotropic pattern or concentric pattern for their 3D printed part.

Embedding of materials into your product is also allowed, where users would be able to decide which layer a pause is needed to carry out the required action

The Eiger software monitors your prints and alerts you if there are any run ins with the product being printed. It also tells you when your print job is paused or complete by sending you an email!

The Markforged is a time efficient printer and no post processing is required as all its parts are ready to be used once removed from the print bed.