U.S. Orthodontic Practice Turns to EnvisionTEC to Provide Cutting Edge Patient Treatments

Dutchess Orthodontics is a medical practice company that has provided the highest quality orthodontic care for over ten years to children, teens, and adults in Hopewell Junction, New York. Dutchess Orthodontics’s treatment objective is not only to straighten teeth but also to balance the face and jaws. The practice provides a range of treatment including, early growth modification such as expanders, aligners, and myofunctional therapy (therapy for the lips and tongue) to help faces and jaws grow properly in children. As patients get older Dutchess Orthodontics provides braces for straightening and improving smile aesthetics, and Invisalign® aligners to help give a more aesthetic smile and correct issues.

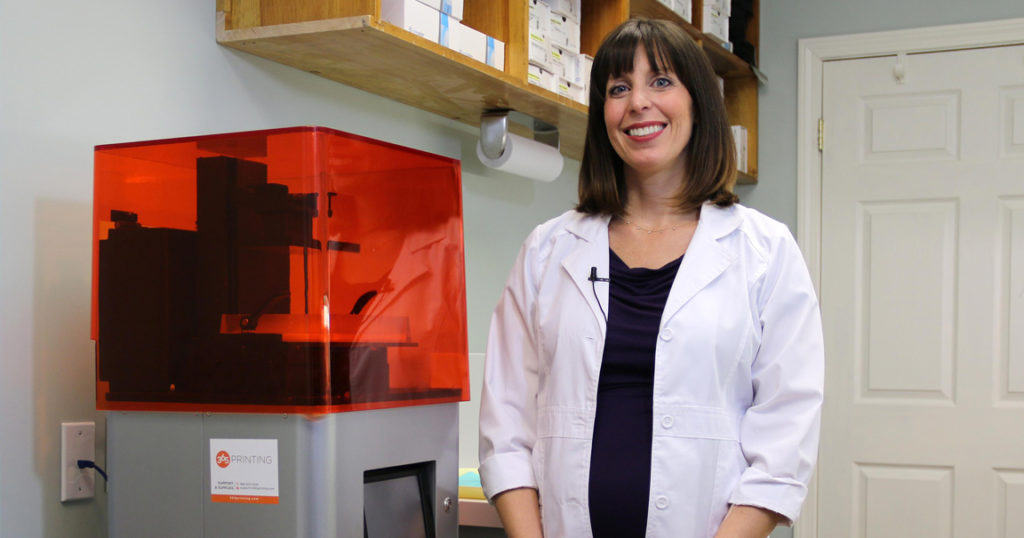

Dutchess Orthodontics believes in creating a friendly environment during orthodontic treatment for children teens & adults.

Why 3D printing?

Dentistry is one of the many industries influenced by 3D printing. Dentists have found countless ways to implement 3D printing into their work, though a few applications, in particular, have become universally popular.

To provide patients with maximum convenience and the best possible quality treatment, Dutchess Orthodontics monitors the industry for advancements and try to stay on top with the latest technologies. One technological advancement is the increased use of 3D printing and digital workflows. Over the course of the past decade, 3D printing is making huge waves in both dental and orthodontic industries.

Recent developments and introduction 3D scanning and printing (CAD/CAM) technology improved the efficiency, accuracy, consistency, and predictability of the treatment outcomes, and is helping to reduce stress for patients through less invasive procedures. The technology is also producing better results, better fitting appliances at reduced costs to both the practice and the patient.

For the team at Dutchess Orthodontics, the implementation of 3D printing was the way to go.

In recent years oral scanners have become more accurate, much faster, and more user friendly resulting in chairside design and milling of high-quality prints of orthodontic appliances. Traditional techniques such as taking alginate impressions then manually producing models from stone or even the taking of alginate impressions and scanning them have a high scope of inaccuracy.

“While we were getting nice appliances and nice retainers with the old techniques, they are nothing like the quality of an intraoral scan and then printing off a digital model. “ – Dr. Kelly Walters, Owner of Dutchess Orthodontics.

This appliance accuracy was a concern of the team. They were interested in implementing 3D printing but ideally wanted to do this in-house to allow them to monitor the process and ensure the accuracy of the finished orthodontic appliances.

Why EnvisionTEC?

Dr Walters and her team were looking for a dental 3D printer that would be easy to operate, integrate with the existing intraoral, and provide fast high-resolution prints. After evaluating many options available in the market, Dr Walters settled on EnvisionTEC 3D printing technology.

“At the American Association of Orthodontics they have a really big meeting every year, and they display all the latest printers, all that we have available to us. I was going back and forth between several printer manufacturers but I had a friend who used an EnvisionTEC Perfactory Vida and swore by it.” – Dr Kelly Walters, Owner of Dutchess Orthodontics

EnvisionTEC has long been a leader in orthodontic 3D printing. The company has several dedicated materials for 3D printed orthodontics that are both CE and FDA approved resins for use directly in the mouth. The materials are proven and in use by hundreds of dental and orthodontic professionals around the world.

After taking the advice and comparing the prints and options from several competitive brands, Dr Kelly Walters recognized both the accuracy and the speed of EnvisionTEC 3D printers and was pleasantly surprised at the cost of the machines and materials.

The materials themselves were attractive, with a large number being both FDA and CE approved for a cross-section of dental and orthodontic applications. While the initial use of the technology within the practice would be for the production of arch models for vacuum-formed retainers, this choice would give the practice the ability to move into the production of other appliances quickly and easily.

Ultimately after considering the options, Dutchess Orthodontics settled on an EnvisionTEC Vida with E-Model material. This 3D printer and material combination would allow them the ability to quickly produce accurate dental arch models.

The Results

The implementation of the EnvisionTEC Dental 3D printer in the practice has improved efficiency, reduced costs, reduced waste, and resulted in better results for patients. The E-Model material has proved a good upgrade from the traditional models. The team finds it much stronger, more durable, and experience less breakage than with stone models.

Patients are already benefiting from the less intrusive process and the increased speed, allowing them to have retainers measured and fitted in only a few days or less. The retainers are more accurate resulting in better results for the patient, better fit, and comfort.

“The Vida has helped our office with the work-flow of creating a retainer. It’s a really clean, hygienic process and ultimately the biggest difference is that I have yet to put a retainer in someone’s mouth and find that it doesn’t fit. That would happen about once a week when we were using the old technology.“ – Dr. Kelly Walters, Owner of Dutchess Orthodontics

Though initially the Vida is being used for retainer models, the team are aware of the flexibility open to them by using EnvisionTEC technology. They know that when they want to move into the production of other orthodontic applications the machine will allow them to quickly and simply change materials.