Whitehurst Gallery uses EnvisionTEC 3D printer for printing custom jewelry

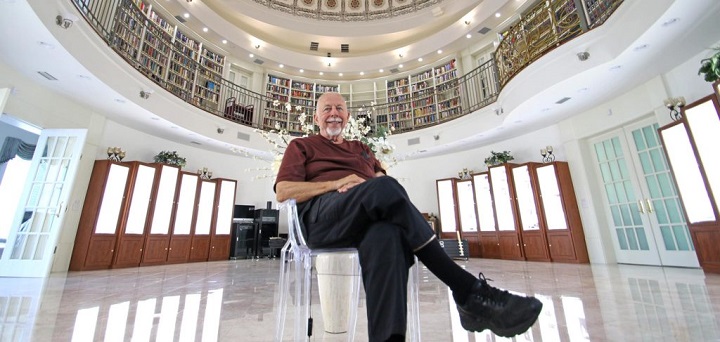

Whitehurst Associated Galleries Inc. (Whitehurst Gallery) is a well-established jewelry manufacturer in Tarpon Springs, Florida, USA. The company consists of a highly skilled team of craftsmen who designs and manufacture intricate custom pieces of jewelry for their customers around the world.

Gareth Whitehurst, the founder of Whitehurst Gallery, has a career of more than fifty years in the jewelry business. He developed his interest in the jewelry industry while working as a part-time in a jewelry store in 1968 (whilst also teaching high school math and playing keyboard in a band!).

Being initially drawn to the business aspects of the trade, he has since embraced the creative elements: enjoying the process of idea generation, translating ideas into designs, and eventually into physical objects.

“With any work, I’ve ever done there has to be a pretty strong creative component in it to maintain my interest and enthusiasm. In jewelry, for example, the variety and spontaneity keep it fresh.” – Gareth Whitehurst, Founder of Whitehurst Gallery.

Why 3D Printing?

For a very long time, Gareth was finding a way for translating his creative designs along with those of the customers and his team accurately into the real world. The jewelry designs can include a wide variety of styles and ideas taken from throughout the history of jewelry.

Gareth was well aware of his skills and knew that as long as he studied, he will be a master of everything. Similarly, recruiting highly skilled employees for every desired work would also be impossible. However, with the advancement in CAD/CAM technology, the need for employing a vast team was no longer required. CAD/CAM technology helps in designs and producing the most complex and intricate jewelry pieces. It also eliminates the need for specific specialist skills.

“I don’t have an unlimited repertoire of personal skills to build things, to undertake master modelling. This technology gives me all those skills that I don’t have at my fingertips. It lets you go anywhere you want to go, create any kind of an impression, or styling. It makes a master out of anybody, it’s a total game-changer.” – Gareth Whitehurst, Founder of Whitehurst Gallery.

By introducing CAD/CAM technology into the business, they are now able to manufacture far more complex and intricate designs that were almost impossible to manufacture through the use of traditional methods.

“If you can think limitlessly, this technology gives you the technique to actually pull it off. Once you have mastered the skill of the software and machine it is liberating, because it lets you be anything you want to be, think anything you want to think in a design sense. You don’t have limitations.” – Gareth Whitehurst, Founder of Whitehurst Gallery.

Why EnvisionTEC?

The improvement in 3D printing technology and materials for jewelry manufacturing have proved very beneficial for manufacturers. The advancement in castable material is particularly helping the businesses by providing more freedom for design, with model casting cleanly every time and retaining the detail.

“As the material quality has improved and the castability has gotten easier this has allowed us to produce more complex pieces, knowing that they will cast cleanly” – Gareth Whitehurst, Founder of Whitehurst Gallery.

EnvisionTEC provides a combination of a wide range of material for a variety of end-uses within the jewelry industry. The Easy Cast material, as an example, has the highest wax content of any premium castable material in the market. Specifically built for the EnvisionTEC cDLM series printers, it provides the ability to work and finish by hand as with traditional waxes. Other materials provide different properties and burnout characteristics depending upon the raw material being cast.

The production of accurate parts not only depends on the quality of material, but it also depends on the machine used. The machine must be capable of producing models with the finest details and smooth surface finish. This was a primary concern to Gareth and his team while searching for the machine.

“High resolution is crucial in the process. We have to see all the details that we have in CAD in the printed models.” – Attila Kuczora, CAD/ CAM Specialist, Whitehurst Gallery.

The team at Whitehurst knew that the production of beautiful models in the computer was pointless if this was not reflected and reproduced accurately by the printer. After seeing the options from EnvisionTEC, it was clear that the machines and materials were the best available.

The team decided to purchase a Perfactory series 3D printer from EnvisionTEC. This 3D printer allowed Whitehurst to produce a large number of models simultaneously. The Perfactory series 3D printer provided high resolution and accurate reproduction of models. As a bonus, the printer was fast and provided the ability to quickly switch materials to match the needs of that particular customer.

“We use EnvisionTEC’s Perfactory to print a lot of models at once. It is very easy to switch out materials. We use PIC 100, sometimes we use Pro Gray and HTM140.” – Attila Kuczora, CAD/ CAM Specialist, Whitehurst Gallery.

Later the team at Whitehurst saw the demo of EnvisionTEC’s cDLM 3D printing technology which was capable of printing parts faster. After seeing demonstrations of the Easy Cast material, the team at Whitehurst Gallery knew that they needed to invest in the new technology.

Adding an EnvisionTEC Micro cDLM in their production process has resulted in the ability to turn around small batches of high wax, castable ring models in a few hours.

The Results

The team uses the machines constantly. The combination of EnvisionTEC 3D printers and materials allows for the rapid production of large models or large numbers of smaller ones for either casting, molding, or prototyping. The EnvisionTEC cDLM high-speed 3D printer allows for intricate castable and moldable parts to be printed in a few hours. This reduces overall production time and waiting time for customers