Guhring UK – Opening Up New Revenue Streams with Additive Manufacturing

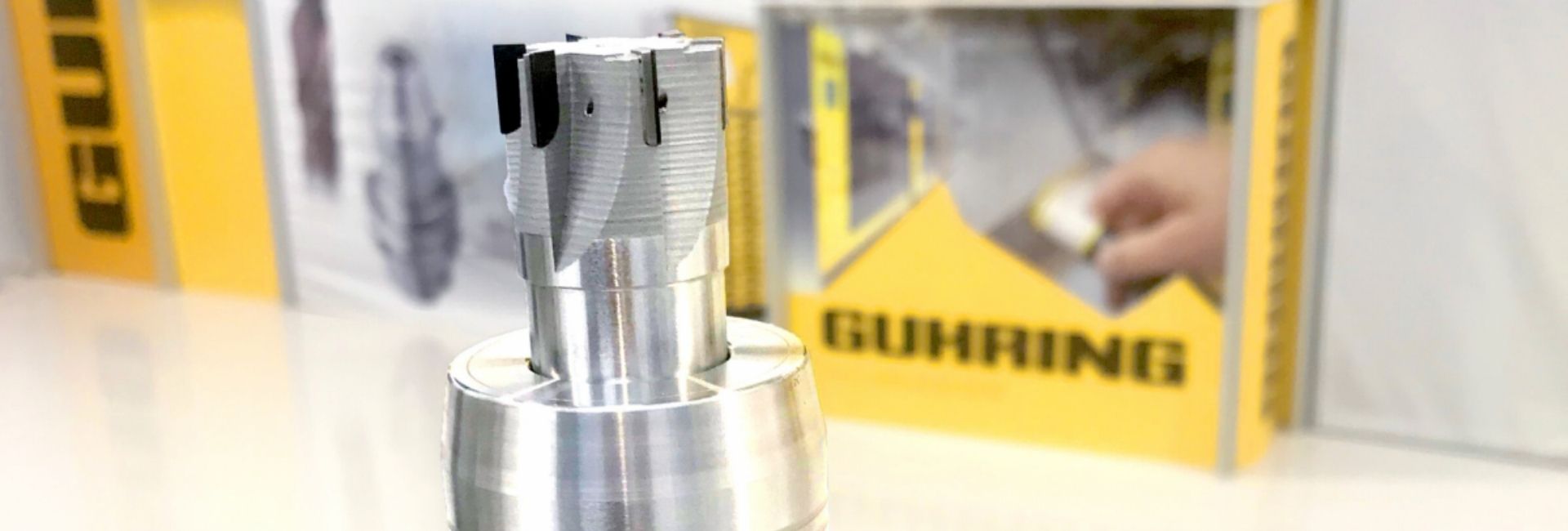

Founded in 1973, Guhring UK — the Birmingham-based subsidiary of the Guhring Group — manufactures precision cutting tools. The company began as a stockholder of the more standardized cutting and milling tools. Today Guhring UK manufactures bespoke cutting and milling tools for some of the world’s largest companies, including BMW, Jaguar Land Rover, Airbus, and BAE Systems. Guhring’s expertise in manufacturing carbide and polycrystalline diamond (PCD) cutting tools is world-renowned. Their range of PCD tools are made-to-order to suit customer requirements and are manufactured by brazing ultra high-hardness industrial-grade diamond cutting tips onto bespoke hardened tool steel bodies.

The Challenge

Each piece of special tooling Guhring UK makes needs to first be designed and approved by the customer. Depending on the size and complexity of the component, special tooling can take up to eight weeks to design, test, and manufacture in-house — and the work can’t even start on the tool until the design is approved. Smaller manufacturers with less volume can’t justify the costs or lead time for special tools.

“As we started looking at supplying smaller volume customers, it became an issue,” says Alan Pearce, PCD Production Supervisor at Guhring UK. This led the company to look into additive manufacturing as an option to open up new revenue streams, reduce lead times for existing ones, and manage timelines for smaller customers.

Download the PDF to know how the Guhring UK is utilizing Markforged 3D printing technology to save time and cost in the production of tooling