How Cashco Increased Production Rates While Keeping Its Toolmakers Happy

Cashco, Inc. is a global industrial control manufacturer that has been in business for over 100 years, with offices in both the United States and Germany. The company specializes in manufacturing control valves, regulators, and vapour control devices for a wide range of industries, from oil and gas to pharmaceuticals.

The challenge

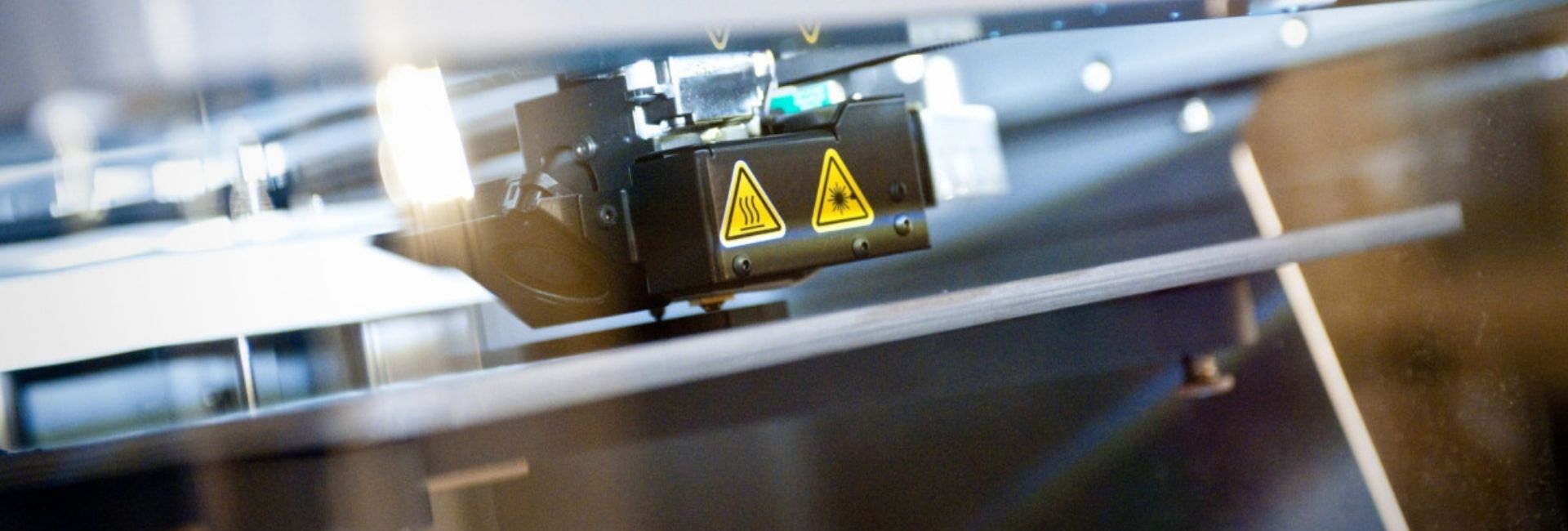

The company requires high-precision parts to manufacture equipment that accurately and reliably controls the flow, pressure, temperature, level, or pH of a process. To meet rising demand, the company uses a large number of robotic arms across its production lines, and each is fitted out with custom sets of tooling. As a company with a long legacy of providing quality products, the company requires expert toolmakers and craftsmen to make and maintain the custom tooling for each robot. Expert toolmakers are hard to find, and the excellent toolmakers Cashco already had were starting to feel the strain of fabricating low-volume custom tools for internal use. Clint knew he and the team would need to think differently to meet customer demand while staying competitive.

Download the PDF to know how the company overcome the challenge, reducing the need for material tooling work by 90%, and lead time by 75%.