3D Printed

Force-sensitive

You can control the robot with your touch, this makes the robot friendly to work alongside humans. The robot can be stopped by inducing shock anywhere on the robot.

60 Seconds to train

No coding, no complex kinematic & no computer. You can train the robot just by moving it with your hands. Onboard storage can save up to 16 independent sequences.

Remote Control (Tele Operation)

Perform tasks remotely for efficiency and convenience from hundreds of miles away.

A single operator can control multiple robots performing tasks quickly and efficiently.

Easy Integration

Installing dexter is extremely easy. Mount the robot on stable platform and make sure it can reach its subject. Plug-in the robot and train it with your hands.

Open Source

Dexter is ideal for schools, R&D projects, and academic studies. Hosted on Github, Thingiverse and moderated via Discord all assets are easily and freely accessible.

Find out more about Dexter Robotic Arm

Unlimited Applications

A robotic arm can do whatever our hands can but better. The use cases are endless.

DEXTER DEVELOPMENT ENVIRONMENT

DDE allows user to program tasks & have precise control over Dexter’s movements

Dexter’s Specifications

The new Dexter HDI brings our award wining robot/cobot platform to the light industrial space with unrivaled precision and affordability.

| Standard Reach | 700 mm |

| Standard Payload | 3 kg |

| Total Robot Weight | 6 kg |

| Repeatability-Point & Path | 0.025 mm |

| Stepping Precision | 5µm |

| Power Cycle Repeatability | Automatic |

| Power Requirments | 40-100W |

| Solar Capable | Yes |

| Degees of Freedom | 7+ |

| Joint Ranges (DOF) | J1-365 degress, J2-200 degrees, J3-270 degrees, J4-240 degrees, J5-J6-J7-360 degrees |

| Joint Speed | 100 degrees per second |

| Tool Speed | 1.2 m/s |

| Duty Cycles | Light Industrial |

| Stored Program Repeatability | Yes |

| Vision System Capable | Yes |

| Control System | 200KHz FPGA |

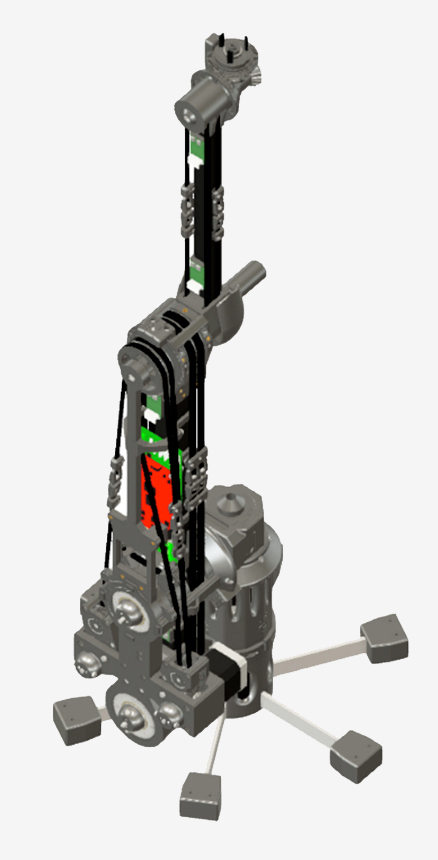

Dexter: 7+ Axis, 3D Printed Robotic Arm

Low-cost, High Precision Desktop Robotic Arm

The Las-Vegas based robotics company Haddington Dynamics designed and manufactured Dexter, an open-source 7+ axis robotic arm to bring cost-effective robotic automation to the masses. Leveraging on 3D Printing technology together with carbon fiber reinforcement, allows the cost of the robot to be low while maintaining high precision. Most importantly, the robotic arm is equipped with innovative technology to perform at a very high level.

One of the key features of Dexter is, it is easy to program even for someone new to robotics or have a basic understanding of code. The secret to Dexter’s performance is the use of a specially-designed FPGA supercomputer. FPGAs are uniquely capable of using parallel processing to simultaneously work through huge amounts of data which gives each of the robotic joints 0.8-1.6 million points of precision (CPR), without sacrificing either speed or precision;

The groundbreaking feedback and control system makes Dexter a fast and precise robotic arm and eliminates all of the sacrifices made by other robots on the market. The very high polling rate also dramatically improves the operator’s safety.

Dexter can be mounted on desktops and plugged into standard wall outlets, giving easy integration into vast variety of environments.

Key features

- The mechanical robotics arms are programmable via software or manually

- The robotic arms consist of segments connected by rotary and linear joints, allowing for controlled, precise and accurate movements

- Robotic arms are attached with end effectors designed for a wide variety of functions such as pick & place, parts rotation & placement, tool handling and assembly. the end effectors can be 3d printed and attached on the robotic arm based on the application.